.

LOGISTICS AND DISTRIBUTION OPTIMIZATION

Top consumer packaged goods company with multiple power brands in food, confectioneries, and beverages uses LogiNext’s superior shipment scheduling and delivery route planning to move millions of units across multiple warehouses and hundreds of connected distribution centers.

HIGH CAPACITY UTILIZATION AND PERFECT ROUTE PLANNING

HIGH CAPACITY UTILIZATION AND PERFECT ROUTE PLANNING

Streamlining Logistics for Multinational CPG Giant

This top consumer goods company, globally famous for their multiple power brands in food, confectioneries, beverages, etc. required proper tech-backed planning and optimization in their distribution. There were more than 50 distribution centers mapped to each warehouse. Due to manual planning and allocation, loading time was high leading to eventual delays and missed delivery timelines.

To ensure high availability of their flagship brands across a high-density retail network, the client wanted to cut down the total lead time from warehouse to distributor and then onwards to retailer. This required high capacity utilization, robust shipment scheduling, fast loading and dispatch, live tracking, and efficient route planning.

The client partnered with LogiNext and within a month it could attain all that they were looking for. They had faster loading times with fast picking and sorting (scanned directly in a central system), machine-learning backed schedule planning and routing, live GPS tracking of trucks, and much more.

This top consumer goods company, globally famous for their multiple power brands in food, confectioneries, beverages, etc. required proper tech-backed planning and optimization in their distribution. There were more than 50 distribution centers mapped to each warehouse. Due to manual planning and allocation, loading time was high leading to eventual delays and missed delivery timelines.

To ensure high availability of their flagship brands across a high-density retail network, the client wanted to cut down the total lead time from warehouse to distributor and then onwards to retailer. This required high capacity utilization, robust shipment scheduling, fast loading and dispatch, live tracking, and efficient route planning.

The client partnered with LogiNext and within a month it could attain all that they were looking for. They had faster loading times with fast picking and sorting (scanned directly in a central system), machine-learning backed schedule planning and routing, live GPS tracking of trucks, and much more.

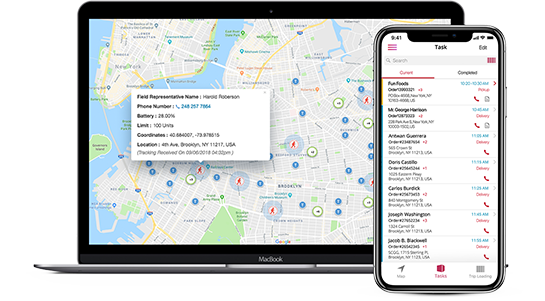

Resource Management

In-depth analytics on how resource management and real-time tracking can boost sales across territories with strategic last mile solutions.

High Capacity Utilization

Capacity of each truck was optimized not just for weight but also for the volume each pallet or crate occupies. Client could deliver more in each trip.

FAST LOADING AND DISPATCH

In-app continuous scanning of items reduced picking, sorting, and loading time. Carrying load was easily balanced across third-party logistics carriers.

PERFECT SHIPMENT ROUTE PLANNING

Shipment was automatically mapped to the best-suited driver and vehicle. The shipment schedule was planned along the fastest routes avoiding traffic.

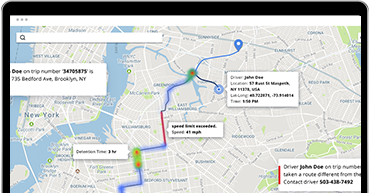

REAL-TIME VEHICLE TRACKING

Live tracking with instant notifications helped the client to ensure end-to-end visibility of all distribution from a single ‘control tower’ dashboard.

REDUCED DELAYS AND COST

Client increased on-time deliveries while moving more shipment per trip, using available capacity to the fullest and reducing overall logistics cost.

Recommended Case Study:

One of the biggest CPG retail chains in the USA, with more than 2000 stores across the country with product line-ups ranging from home & personal use to official & commercial merchandise, uses LogiNext to decrease resource cost and boost productivity!

Recommended White Paper:

One of the largest quick service restaurant chains with sales of more than $24 billion from more than 15000 restaurants across the world looks to establish dominance in their on-demand delivery management module with expert delivery route planning.

© 2022 LogiNext Solutions | Terms & Conditions | Privacy Policy

Subscribe to our Newsletter